How durable are Tensar geogrids?The durability of any geogrid is dependent on two main factors; the polymer composition and the environment in which it is placed. Tensar uses high quality polypropylene and HDPE in the manufacture of all geogrids which are recognized as effectively inert to all common in soil degrading mechanisms. Tensar geogrids are manufactured under a strict Quality Control regime and are required to satisfy the durability requirements in independent approval documentation and audited manufacturing procedures.Please contact Tensar for additional information. Why should I use Tensar products when I can find a cheaper alternative?Clearly, not all products are of the same quality. Tensar produces independently tested, high quality products, with a long track record of proven performance, based upon extensive research and development.

Tensar offers a range of services to support the use of our products and systems in your application. Designs using Tensar products and systems are based upon the unique characteristics of those products and systems and the use of alternatives should be accompanied by a design suitable for those products and systems. What are the limits and parameters for Tensar reinforced soil in terms of size, angle and finish?There is a wide scope for Tensar geogrid reinforced soil structures. Near vertical single structures over 65ft (20m) high and stepped structures up to 195ft (60m) have been designed and constructed. However specific design limits can only be determined once the specific conditions of the project and requirements for the application are known.

Please contact your local Tensar representative at an early stage of your project to determine whether Tensar products and systems can be used. We can assist in developing a concept or designing it for construction based on your project needs. We received a Tensar design and supply proposal/quotation some time ago and would like to place an order in the near future. What do I need to do?The main concern is to ensure that there are no changes to the project which might impact our original design. We would require current project information in the form of an updated plans and specifications. After reviewing this information we would either confirm that the original design is still applicable or provide a revised design.

We will notify you of any cost implications associated with redesign or price increases associated with time lag and requote if necessary. Please contact your local Tensar Representative to discuss the project and notify any changes that may have been made to the original design brief. Can someone come on site to show us how to install the Tensar products and systems?A site visit at the start of construction may be offered as part of Tensar’s standard Design & Supply service. The purpose of this visit is to describe and demonstrate the techniques required to correctly install Tensar products on your project. We strongly recommend that all contracting personnel involved in installation are present for our construction sequence demonstration including the system designer and QA/QC personnel.

Please contact your local Tensar Representative to arrange a site visit. Generic construction sequences for the various Tensar structures are also available on the website at www.tensar-international.com. What is the difference between an Application Suggestion/Conceptual Design and detailed design?An Application Suggestion/Conceptual Design is a preliminary concept whose purpose is to demonstrate whether and how a Tensar product or system could be used to satisfy the project need. It is generally based on incomplete or assumed information and is therefore not intended for construction. Tensar can undertake a detailed design involving Tensar products and systems. A detailed design provided by Tensar is intended for construction and is based upon clearly defined information provided by you or your consulting engineer, which is contained in a design report/Design Brief.

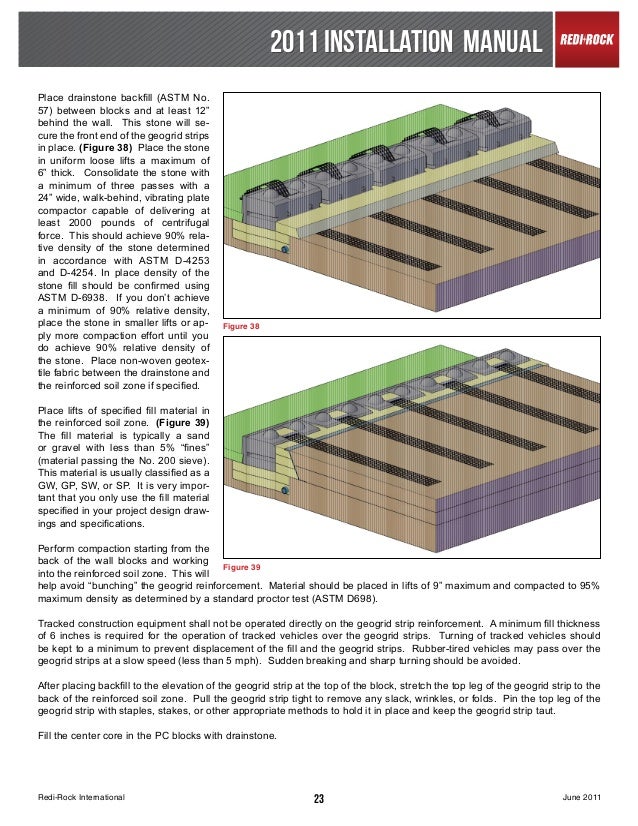

Geogrid Installation Details

In the US the detailed design will be sealed by a professional engineer. Can we further optimize the Tensar wall design you have provided?Possibly as this depends on a number of factors. The wall design is based on information provided by you to Tensar as summarized in the design report/Design Brief. The design has been developed by the Tensar design team as the most efficient and cost effective design applying design parameters contained in the design report incorporating Tensar products and systems. Contact your local Tensar Representative to discuss options for optimization considering cost, constructability and other factors. Can we change the soil parameters?Yes.

Mirafi Geogrid Installation

Tensar is not responsible for establishing soil parameters and relies on information provided by you or your consulting engineer. This information is contained in the design report which sets out the advice you or your consulting engineer have provided. The design report/Design Brief forms the basis for Tensar design of a structure incorporating our products and systems. If the soil parameters on which the design is based have changed a new design report, incorporating these changes, is required and a new Tensar design will be provided to you.

Installing Geogrid Soil Reinforcement

This may involve additional costs for substantial changes.

SCOPEThis Method Statement refers to various work procedures contained within project Control Documents, which explains and covers the installation of Domestic water pipework (Hot & Cold)3. RESPONSIBILITIESEngineer In-charge (Plumbing) / Site Engineer (Plumbing)4. TOOLS / EQUIPMENTSPortable Hand toolsPortable Drill machinesSolvent for uPVC jointsPolypropylene welding machine (Thermo fusion machine)5. MATERIALSHot & Cold water piping material shall be as per approved material submittals.Hot water piping: PEX: All concealed Hot water pipingPPR: All piping up to 4 inchesCopper: All piping above 4 inchesCold water piping: PEX: All concealed cold water pipingPPR: All piping up to 4 inchesUPVC(ClassE-3505): All piping above 4 inches.6. HANDLING & STORAGEOn receipt of Domestic water pipes & fittings, the materials shall be handled & stored in line with the following procedure:6.1. Pipes will be stacked on a flat surface free from sharp projections, stones or other objects likely to caused point loading or pipe deformation.6.2. The storage area shall be kept in proper level, so that the stacked pipes may be uniformly supported throughout their length.6.3.

Pipes will not be dropped on hard surfaces and will not be dragged along the ground. Wherever possible the loading and unloading of pipes will be carried out manually by hand.6.4. If mechanical lifting equipment is used, ensure no metallic slings, hooks or chains will be used in direct contact with the pipe. Rope or nylon belt sling will be preferred which will not damage or cut the pipe surface.6.5. Pipe of different sizes or wall thickness will be stored separately or where this is not possible, those with larger diameters and / or thicker walls will be placed at the bottom of the stack.6.6. The stacks will be protected from direct sunlight by covering with tarpaulin sheets.6.7.

All the pipe fittings will stored in the boxes as supplied by the fittings manufacturer.7. INSTALLATION PROCEDURES7.1 HOT WATER SUPPLY PIPES (PPR)Area of installation: All piping up to 4 inches7.1.1 All installation shall be made as per approved shop drawings.7.1.2 Approved polypropylene pipes, fittings and valves shall be used for installation.7.1.3 Prior to installation the pipes and fittings shall be cleaned properly.7.1.4 All supports shall be installed ensuring correct alignment of pipes and location as per manufacturer recommendation.7.1.5 UPVC(class-E to BS 3505).

7.1.18 Drain valves shall be installed in the lowest point & Air Vents shall be installed in the highest point as per requirement at site during installation.7.1.19 Water Hammer Arresters shall be installed as per approved shop drawings. (Stress analysis on water supply system and to consider all necessary measures to ensure that the system is water hammer free).7.1.20 After getting approval for installation of pipe works, the system will be tested @ 8 bar for 6 hours.